ZLTECH ( Zhongli Laser ) manufacture various laser machines, including fiber laser cutting machine, laser welding machine and laser cleaning machine. ZLTECH products own CE, FDA and ISO certificates. Every machine will be tested well before shipping. ZLTECH supports OEM and ODM service. ZLTECH established a complete and strict quality control department, which controls the product quality from raw materials, production and delivery. Every equipment is finished with fine milling and high-temperature aging treatment. Also ZLTECH use high-tech precision instruments to measure the accuracy and transmission speed of the machine.

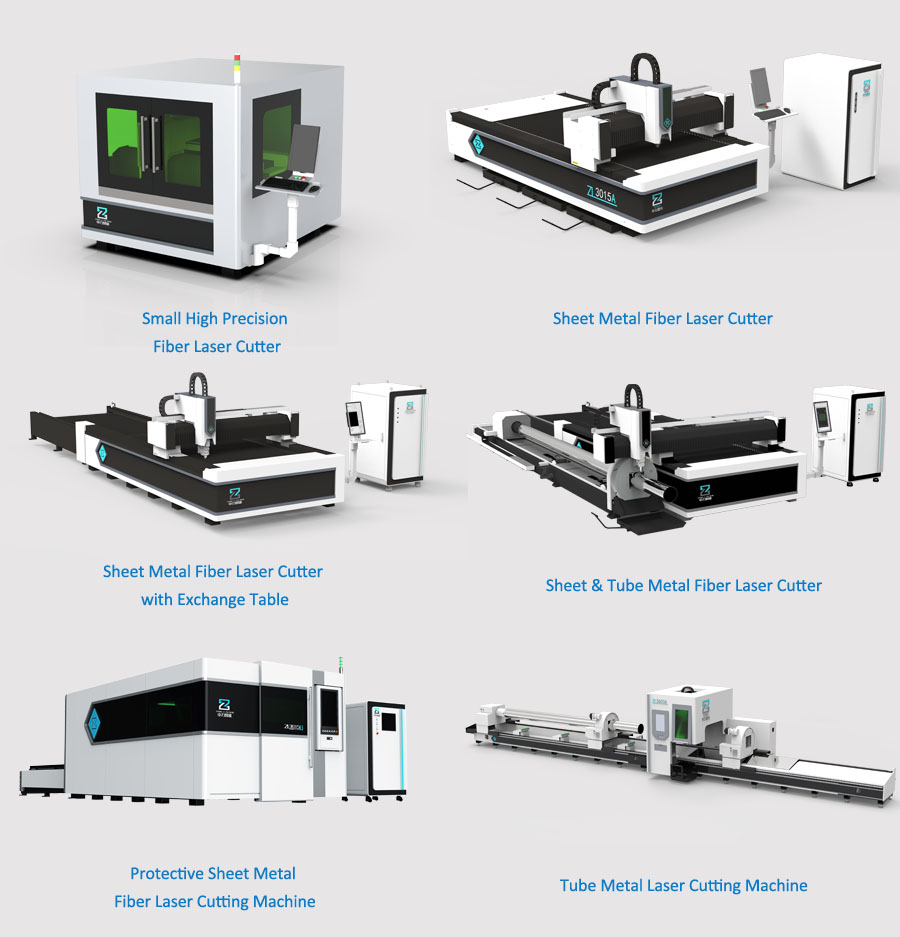

Fiber Laser Cutting Machine :

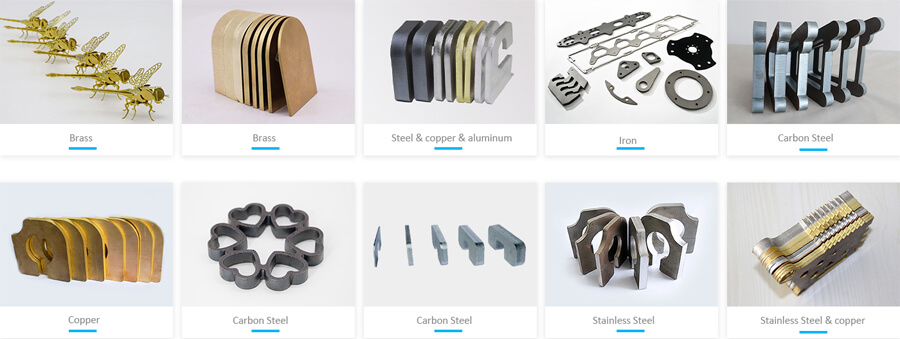

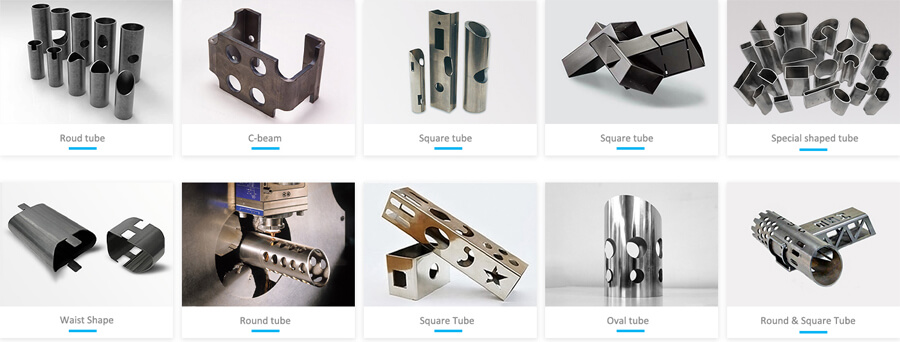

Fiber laser cutting machine can help us cut many different metals, such as stainless steel, carbon steel, aluminum, brass, copper, etc.

Different thickness need different laser power. ZLTECH provides customization service.

Laser Welding Machine :

Fiber laser welding machine can be used to weld various metals and alloys such as stainless steel ,carbon steel,copper,aluminum,gold,silver,chromium,nickel,titanium,etc.

It is widely used in the complicated and irregular welding processes of cabinets and kitchens,stair lifts,shelves,ovens,stainless steel doors and windows guardrails,distribution boxes,stainless steel furniture,metal sheet metal and other industries

Technical Parameters :

Model: ZLW-1500W/2000W/3000W

Laser type: Fiber laser,1064nm

Laser power: 1000W/1500W/2000W

Cable length: 7 meter

Welding speed: 0-120mm/sec

Welding thickness: 0.5-5mm

Cooling method: Water cooling

Gas assist: Nitrogen/Argon

Visual positioning: Red dot

Product Advantages :

Simple operation,greatly reducing labor costs.

Indirect radiation is small.

Fast speed and efficiency is 3-8 times that of argon arc welding.

Concentrated energy and little influence of thermal deformation.

Fine welding seam,deep molten pool,high strength.

Very thin materials can be welded,such as 0.05mm stainless steel.

Both autogenous welding and additive welding are Ok .

Laser Cleaning Machine :

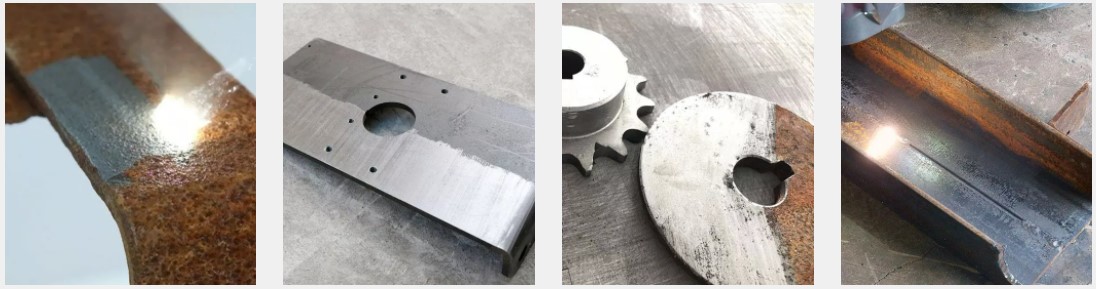

Handheld laser cleaning machine and surface preparation system designed to remove rust, paint, and almost anything else from steel, aluminum, iron, and many more surface types. This handheld laser cleaning machine surpasses the capabilities of standard sandblasting and dry-ice blasting by a long shot. It is the most cost-effective, efficient, and safe method of industrial cleaning, rust removal, paint removal, and surface preparation.

Laser cleaning processes work best when the unwanted layer has a high absorption rate within the laser's wavelength range and the underlying substrate is reflective within the same range. This relative absorption difference causes the unwanted material to heat up quickly and ablate from the surface—leaving the substrate unaffected. A fume extraction system then removes the airborne material in a clean and controlled manner.

TECHNOLOGY BENEFITS :• Fast set-up

• Easy to operate

• Quiet

• Leaves no residue

• Highly reliable

• Easy to automate

• Low operating costs

• Virtually maintenance-free

• Green process - no pollution

• Laser beam settings are precisely adjustable to optimize process speed & gentleness